Which are the tools we use for the sense development

Our roadmap has currently 3 stages:

- Testing (PoC) of the device with organizations of the visually impaired in the D-A-CH area (sense V0.6)

- Design of a final PCB layout, incl. all components: microcontroller, USB, power management, sonar, accelerometer, ToF laser, filter, haptic actuator (sense V0.8)

- Provision of a production release of the device (sense V1.0)

In this blog we speak about first steps, but focused on step 1.

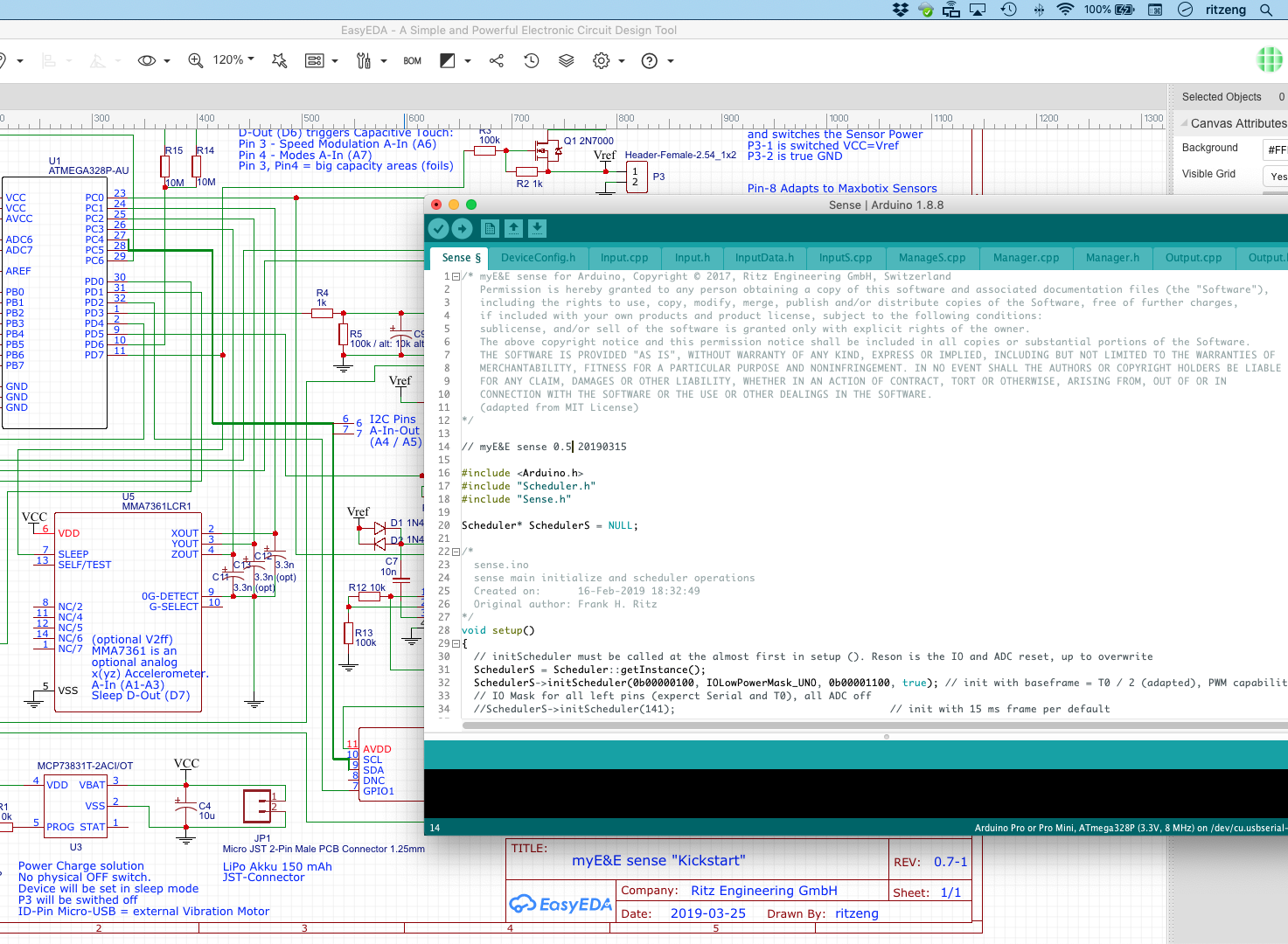

C++ Development

Arduino • mtos • Sonar • ToF Laser • Accelerometer

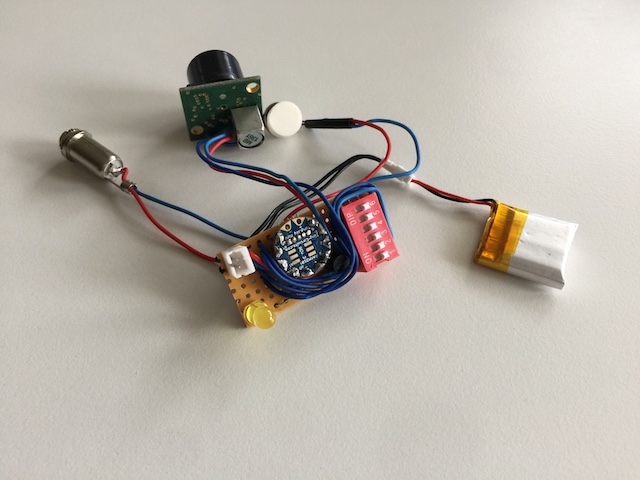

We focus on a small, cheap and simple device and decided for the Atmel ATmega328P of the Arduino C++ environment, and developed a small task oriented OS (mtos) which covers all aspects of energy savings, deep sleep, scheduling, timing, interrupts and asynchronous operations for development, testing and production. Our roadmap prioritizes the development of the hardware and a minimal software functionality to get early user experiences.

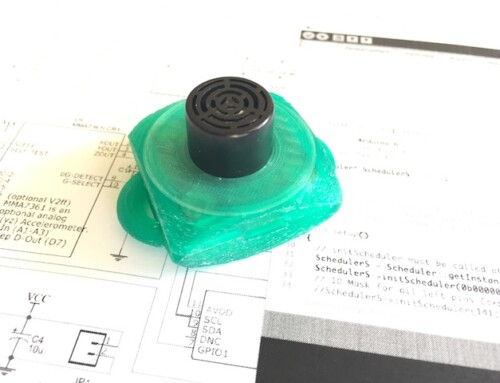

The main sensor is a sonar sensor, which we developed ourself (V0.8). For the stage 1 we use a commercial product (SRF02 / URM07), which is very similar to ours and provides the same end user experience.

In stage 2 (V0.8), additionally to our own sonar sensor, a Time of Flight laser class 1 sensor and an accelerometer will be integrated to complete the hardware configuration. On this hardware the specified software requirements to recognize obstacles and obtain precise, sharp and fast measurements will be integrated.

PCB Design, 3D Print, Assembly

EasyEDA • JLCPCB, PCBWAY • 3D Print • Variants

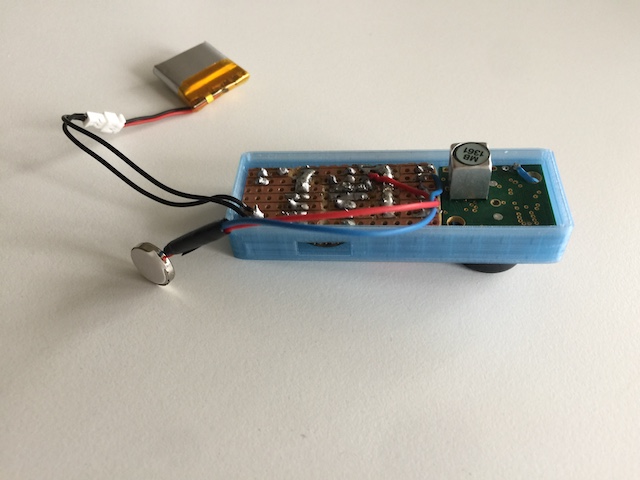

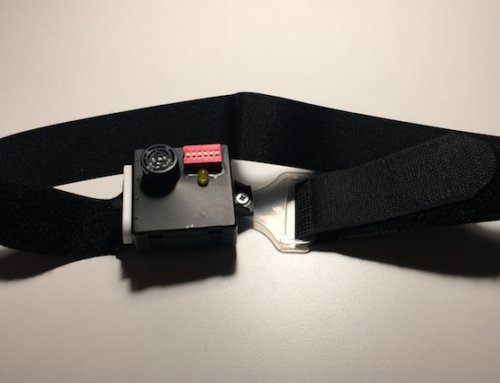

The current body is 34 * 34 * 17 mm and as shown. For stage 1, the body is a 3D print (PLA), where there are variants for the portable functions (strap, eyelet, clip, forehead or bracelet). 3D Prints are designed with Tinkercad and Cura. The PCB design is done with EasyEDA.

Stage 1 (10 pieces V0.6) is produced with JCLPCB, where we mount all electronic parts (SMD 0805) and equip the PoC ourself. This is the reason why we buy the sonar component.

Currently the electronics, schematic and PCB layout is completely developed but not produced as PCB for stage 2.

Stage 2 (V0.8) will be produced with PCBWAY, which mounts all electronic parts on the PCB with the smallest possible package. The PCB cannot be further mounted manually because of the components sizes (SMD 0402, HVQFN, LGA) and solder techniques. The body will still be 3D printed (PETG).

It is planned to produce a pre-Kickstarter Version of 20-30 pieces with the stage 2 configuration.

Note.: Images contain V0.5 and V0.6 body.